Engineering News, Volume 71, No. 1, Jan. 1, 1914, pgs 34-42.

On Jan. 22, 1913, a large new theater in New York City, under construction and nearly completed, was wrecked by the collapse of most of its roof and the interior balcony. Little more than the walls and auditorium floor remained. The collapse occurred only 20 minutes after quitting time and the last of the 200 workmen employed on the building had only just left when the structure fell. Fig. 1 shows the interior just after the collapse.

A brief account of the accident was published in our issue of Jan. 30, 1913, p. 234, but at that time the steel framing was largely covered by the debris and it was impossible to report on the condition of the parts and the circumstances as shown thereby. Later examination showed a remarkable and puzzling state of affairs. We

have refrained from dealing with it until the issuance of the report on the collapse by the Bureau of Buildings of Manhattan Borough. This report, rendered last May, by Alfred Ludwig, chief inspector, to R. P. Miller, Superintendent of the Bureau, was not made public until a few weeks ago.

have refrained from dealing with it until the issuance of the report on the collapse by the Bureau of Buildings of Manhattan Borough. This report, rendered last May, by Alfred Ludwig, chief inspector, to R. P. Miller, Superintendent of the Bureau, was not made public until a few weeks ago.Other information is also available now: We have secured an opinion from the steel contractors, National Bridge Works, by T. J. Foster, President; and have copies of report made by four consulting engineers retained by the general contractor, Fleischmann Bros. Co., to investigate the collapse: Robt. W. Boyd, Laurence A. Ball, Tho. J. Bard, and Weiskopf & Burroughs, all of New York City. The four investigations were made independently of each other and of the investigations by the Bureau of Buildings and by the steel contractor.

The various opinions on the collapse differ radically. The engineers outside of the Bureau of Buildings present three different explanations of cause. Chief Inspector Ludwig's report, on the other hand, considers all three explanations as open to objection, and does not conclude in favor of any. A further remarkable feature of the case is that each of the three explanations is highly interesting in itself, two of them at least involving conditions practically unprecedented in structural failures.

The various opinions on the collapse differ radically. The engineers outside of the Bureau of Buildings present three different explanations of cause. Chief Inspector Ludwig's report, on the other hand, considers all three explanations as open to objection, and does not conclude in favor of any. A further remarkable feature of the case is that each of the three explanations is highly interesting in itself, two of them at least involving conditions practically unprecedented in structural failures.The points involved in the collapse include: tension failure; buckling of columns; stability of a cantilever system of support; overloading by excess concrete; excessive stresses; and quality of material.

The Orpheum Theater, 168-180 East 87th St., New York City, was being built by Fleischman Bros. Co. for the Loew Theatrical Enterprises. Thos. W. Lamb was architect for the latter. The National Bridge Works,

New York City, built and erected the steelwork. The steel erection was begun in the early part of November 1912, and the last of the truss work was set before the end of December. Floor and roof concrete, plastering, etc., went on in January. On the day of the collapse, the interior trim and some minor framing alone remained to be placed.

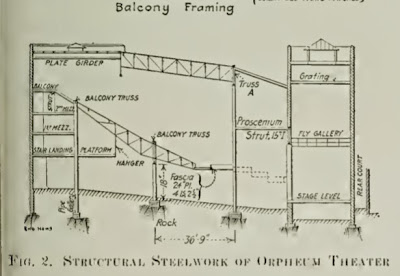

New York City, built and erected the steelwork. The steel erection was begun in the early part of November 1912, and the last of the truss work was set before the end of December. Floor and roof concrete, plastering, etc., went on in January. On the day of the collapse, the interior trim and some minor framing alone remained to be placed.The structural part of the building is drawn in Fig. 2, containing plan of roof, plan of balcony, and longitudinal section. In the two plans the portion which collapsed is indicated.

The roof over the auditorium was carried by two large transverse trusses, the rear one resting on the side wall and the forward one resting on two columns, each about 7 ft. inward of the walls. The two trusses supported longitudinal secondary trusses and transverse I-beams.

The balcony was of the usual cantilever construction. A transverse truss resting on two short columns near the side walls carried the balcony. Three steeply inclined cantilever trusses extended over this transverse truss, their rear ends being attached to the floor framing in the rear part of the theater

at one of the upper levels, while the forward end carried the plate-girder balcony fascia rail. The balcony fascia girder, curving forward along the sides, extended as far as the high columns supporting the forward roof truss, and the ends of the girder were attached to these columns. Some beam framing for boxes at the balcony level between this column and the proscenium wall was not in place at the time of the collapse. With this exception the balcony framing was complete, and, as already mentioned, the concrete floor slab, stepping, etc., was in place.

at one of the upper levels, while the forward end carried the plate-girder balcony fascia rail. The balcony fascia girder, curving forward along the sides, extended as far as the high columns supporting the forward roof truss, and the ends of the girder were attached to these columns. Some beam framing for boxes at the balcony level between this column and the proscenium wall was not in place at the time of the collapse. With this exception the balcony framing was complete, and, as already mentioned, the concrete floor slab, stepping, etc., was in place.The auditorium floor was directly on the ground.

On Jan. 22, 1913, the workmen in the building left at 5 o'clock; about 5:20 the roof and balcony fell in. There was no extra weight on roof or balcony, and everything was quiet a moment prior to the collapse. No indications have been found that point to any kind of violence or malicious damage; the building apparently just broke down. No one was injured.

On Jan. 22, 1913, the workmen in the building left at 5 o'clock; about 5:20 the roof and balcony fell in. There was no extra weight on roof or balcony, and everything was quiet a moment prior to the collapse. No indications have been found that point to any kind of violence or malicious damage; the building apparently just broke down. No one was injured.The plan sketch, Fig. 3, indicates the lay of the principal

parts of the fallen framework after the accident, as determined when the concrete, timber and other miscellaneous wreckage had been removed.

parts of the fallen framework after the accident, as determined when the concrete, timber and other miscellaneous wreckage had been removed.All parts of the roof depending on the forward roof truss (the truss supported on the two long columns) fell; as indicated in Fig. 3, the truss moved back or eastward in the fall, no doubt because the longitudinal trusses pivoted around their attachment to the rear truss until they broke away, and thus pulled the forward truss back. The longitudinal trusses, as well as the forward truss itself, remained whole (without breaks) and still connected to each other at their junctions. The rear

truss was somewhat damaged by the wrenching away of the longitudinal trusses, but otherwise stayed in place undisturbed. The two long columns supporting the forward roof truss buckled each in four segments, lying, as indicated in Fig. 3 and shown by Figs. 9 and 10, in the shape of a closely compressed and twisted Z. It was evident that the roof fell because the long columns buckled under it.

truss was somewhat damaged by the wrenching away of the longitudinal trusses, but otherwise stayed in place undisturbed. The two long columns supporting the forward roof truss buckled each in four segments, lying, as indicated in Fig. 3 and shown by Figs. 9 and 10, in the shape of a closely compressed and twisted Z. It was evident that the roof fell because the long columns buckled under it.The entire balcony fell, with buckling of its two supporting columns and breaking of the main transverse truss in the bottom chord. The structure swung back (east) as the three cantilever trusses remained attached to the upper floor framing at their anchorage end. The south half of the balcony truss came down in practically vertical position, the center and south cantilevers breaking apart through the gusset and flange splice at the angle of the bottom chord. The north cantilever did not break, and tipped the north end of the supporting balcony truss (see Fig. 8) somewhat forward. The breaks in the two southerly cantilevers, being in the lower (compression) chord, doubtless happened when the front ends struck the ground.

The balcony fascia girder, 24 in. deep, remained attached to the two roof columns as well as to the three cantilever trusses. It was folded back on the balcony cantilevers in the middle portion.

The facts concerning the three important points of failure in the collapsed steelwork are noted as follows:

BALCONY TRUSS--Bottom chord broken squarely in two on the center line of the field splice, located between middle and north cantilevers. Just above here, top chord bent and partly broken, and several web members bent or broken (Figs. 6 and 7). Vertical of web showed well contracted tension failure, with reverse bends at top and bottom. Truss remained connected to its supporting columns at the end, except that the bottom-chord attachment at the south column was wrenched off, the column buckling between the two chords as well as below the truss. Truss chords of T-section (two angles, stem-plate and flange-plate). Bottom-chord splice which broke comprised side splice-plates and flange splice-plates. Break was clean and square, through rivet holes nearest the joint, the fracture faces of crystalline texture. Spliced chord-section was 2 angles 8 x 8 x 3/4 in., 1 web 18 x 3/4 in., 1 flange-plate 18 x 3/8 in.

(Dotted lines in plan of bracing indicate axis said to be least braced.)

BALCONY-TRUSS COLUMNS--Length 18 ft. from base to bottom chord of truss, 27 ft. from base to top chord. Section H-shaped, 12 x 12 in. (four angles and web plate). Cap plate of column 6 ft. above bottom chord of truss, and upper joint of truss developed into a shoe with flat base seated on the column cap and riveted to it (Fig. 12). Both columns broke or buckled at the bottom chord of the truss, and the south column also buckled at its cap (see views Figs. 13 and 11). The base of the south column moved off its grillage, but remained just alongside; the north column slipped far away from its grillage. The columns were unbraced, except by their connection to the balcony floor-slab, and at the top by a strut to the wall.

BALCONY-TRUSS COLUMNS--Length 18 ft. from base to bottom chord of truss, 27 ft. from base to top chord. Section H-shaped, 12 x 12 in. (four angles and web plate). Cap plate of column 6 ft. above bottom chord of truss, and upper joint of truss developed into a shoe with flat base seated on the column cap and riveted to it (Fig. 12). Both columns broke or buckled at the bottom chord of the truss, and the south column also buckled at its cap (see views Figs. 13 and 11). The base of the south column moved off its grillage, but remained just alongside; the north column slipped far away from its grillage. The columns were unbraced, except by their connection to the balcony floor-slab, and at the top by a strut to the wall.(South column at left, has been blamed for the collapse.)

ROOF COLUMNS--Section H-shaped (four angles and web-plate). 12 x 12 in.; length 60 ft. from base to bottom chord of roof truss. Cap, and connection to truss, similar to detailing of balcony columns. Each column was held at top and bottom and at two intermediate

points. The points of bending or buckling in both columns are at the two points of bracing (the lower one where the balcony fascia girder was attached and the upper one where a 15-in. I-beam strut to the proscenium girder was

points. The points of bending or buckling in both columns are at the two points of bracing (the lower one where the balcony fascia girder was attached and the upper one where a 15-in. I-beam strut to the proscenium girder was  attached), and at the bottom chord of the roof truss. The location and character of the bracing is shown by Fig. 1.

attached), and at the bottom chord of the roof truss. The location and character of the bracing is shown by Fig. 1.The tops of the columns remained attached to the roof truss, and the bases remained close to their grillages, but tore away from them, without, however, destroying the footings. In addition, the columns showed some twist around the longitudinal axis. The general

lay of these columns is shown in Fig. 3. Figs. 9, 10 and 11 are views of these columns.

lay of these columns is shown in Fig. 3. Figs. 9, 10 and 11 are views of these columns.OVERLOADING BY EXCESS CONCRETE--The New York Building Code allows a steel stress of 16,000 lb. per sq.in. The transverse truss of the balcony at the time of the collapse was stressed in many of its main members to from 22,000 to 24,000 lb. per sq.in., and this with no live-load on the floor. The bottom-chord splice of the balcony truss was stressed to 22,000 lb. per sq.in. The cantilever trusses were similarly overstressed.

The balcony columns also were overloaded. A careful estimate of the actual weight in place, by Asst. Engr. E. F. Hammel, of the Bureau of Buildings, showed a load of 365,000 lb. on each column (R. W. Boyd estimated 396,000 lb.) equivalent to 14,600 (15,850) lb. per sq.in., which is 50% higher than permissible under the Building Code and about the same amount higher than the designed dead-and live-load.

The two tall roof-columns were loaded above balcony level to 166,000 (151,500) lb., equivalent to 7800 (7150) lb. per sq.in. This is higher than intended by the design. The relation of load to probable capacity of these columns is a delicate question on account of their indeterminate bracing. The load at time of collapse was about equal to the designed dead- and live-load.

(Seen looking east, toward balcony. North column, at left, is shown again on the next page.)

Part of the over-stressing was due to underestimate of proper load and errors of calculation. Most of it, however, was due to great overloading by excessive thickness of concrete, fireproofing, slabs and filling.

BRACING OF ROOF COLUMNS (Fig. 4)--Each column was made in two erection pieces, joined by a field splice just below the balcony fascia-girder attachment. The upper section had a shop splice near the upper bracing point. The web of the H-section of the column was north-south, i.e., transverse to the building. In this transverse direction the column was held (between base and cap) only at the balcony level, by the fascia-girder attachment and by an 8-in. I-beam strut running to the wall and intended to be anchored to the wall. R. W. Boyd reports this strut in the case of the north column

BRACING OF ROOF COLUMNS (Fig. 4)--Each column was made in two erection pieces, joined by a field splice just below the balcony fascia-girder attachment. The upper section had a shop splice near the upper bracing point. The web of the H-section of the column was north-south, i.e., transverse to the building. In this transverse direction the column was held (between base and cap) only at the balcony level, by the fascia-girder attachment and by an 8-in. I-beam strut running to the wall and intended to be anchored to the wall. R. W. Boyd reports this strut in the case of the north column  as not being bricked into the wall but simply set into a recess.

as not being bricked into the wall but simply set into a recess.In the east-west direction, i.e., at right angles to its web, the column was braced at the balcony level (about 19 ft. above its base) by the attachment of the balcony fascia-girder to one flange of the column, through a 15-in. channel connection about 10 in. long. About 19 ft. above this point it was braced forward to the truss over the proscenium opening by a 15-in. I-beam strut: this was about 19 ft. below the roof truss.

CONDITIONS AT BALCONY TRUSS COLUMNS--The balcony truss columns were unbraced between base and cap, and, due to the elastic distortion of the balcony framing, the columns would be subjected to some shift of the top and consequently exposed to bending stresses. The connection of the truss shoe to the top of this column being formed by riveting together the flat shoe-plates and by a splice-plate outside, the column can be regarded as continuous from top of truss to base of column, or 27 ft. long. This column was held to the balcony by its attachment to the balcony truss, by a clip-angle connection to a 15-in. I-beam curb, and by a 12-in. beam to the

wall just below the top chord, with connection to longitudinal mezzanine framing.

wall just below the top chord, with connection to longitudinal mezzanine framing.The various reports describe the materials and workmanship of the structure as excellent. The column foundations also being found in good shape when the wreck-pile had been explored, there remained for consideration only the three main failures: roof-columns, balcony-columns and balcony-truss. The conditions existing in the structure were such that any one of the three causes might have been the primary happening, and in each case the general result would have been about that displayed by the collapse.

Three of the consulting engineers reporting to Fleischmann Bros. Co. blame the buckling of the roof columns for the start of the collapse. One of the engineers singles out the north column (Col. 2).

Weiskopf & Burroughs state essentially:

Had these columns been properly supported at about the third-points they would not have failed, and we are of the opinion that good and sufficient supports could have been provided. Considering the fact that the lateral supports for the columns were connected eccentrically, we are of the opinion that these columns had very little, if any, support at these points. ...Our conclusion is that incipient failure was due to insufficient lateral support of Cols. 1 and 2 and that the remainder of the collapse followed as a natural sequence. It is, of course, impossible to conclude which column failed first.L. A. Ball reports as follows:

In my opinion this collapse was due to the faulty design of the structural steelwork in not providing sufficient bracing for Cols. 1 and 2. The bracing which was provided was not only inadequate, but increased the tendency of these columns to buckle, and inasmuch as these columns were not adequately braced they were virtually unsupported from top to bottom and just prior to the time of the collapse had reached a point of incipient failure due to the dead-load intensified by the eccentric connection of the balcony fascia support.The case for the failure of the roof columns is given most fully by R. W. Boyd, who refers specifically to the north column:

At the time of collapse this column above the balcony was carrying a load of approximately 76 tons and was being subjected to a compressive stress of 7140 lb. per sq.in. The connection of the fascia girder with the column added an additional load. ...Assuming the 8-in. beam at the fascia-girder connection as of no value as a tie or strut, as was the case (the beam not having been bricked into the pilaster), Col. 2 throughout practically its full height was free to deflect in a direction perpendicular to an axis approximately parallel with the 15-in. I-beam at the level of the proscenium girder. It will be seen that the fascia girder connection and the connection of the 15-in. I-beam provided little, if any, restraining influence against deflection in a direction perpendicular to this axis. The radius of gyration of the column section about this axis, as indicated in the sketch, was approximately 4.58 in. Assuming the column as unsupported from the top of the grillage to the first rivet-hole in the connection for the bottom chord of roof truss, it will be noted that the column had a ratio 1/r of approximately 156.Section 138 of the Building Code fixes the safe unit-stress in columns as 15,200 -- 58 1/4. limiting the value of 1/r to 120. From the figures given above it is apparent that this column as constructed was beyond the limits of the Building Code formula. Applying the formula, however, for purposes of comparison only, we find that the safe stress for the column was 6150 lb. The actual stress (7140) exceeded this figure by approximately 16%. In the case of a column such as the one in question designed with a single web and with a maximum diameter of 12 3/4 in. and a total unsupported length of nearly 60 ft. and built up in three sections with riveted splices, I am of the opinion that even a ratio of 1/r of 120 is excessive, and notwithstanding the provision of the Building Code a column under such circumstances should be designed on a much more conservative basis. With such a column, considerations such as the liability of inaccuracy of fabrication, the danger of damage in handling, and the great difficulty in making two splices so that the axis when erected is a straight line and truly vertical are of much greater importance in the determination of the safe stress than a theoretical column formula based on more or less ideal conditions. Col. 2 under the imposed load was, in my opinion, in a dangerous condition * * * *

An examination of the construction adjoining the columns and rigidly connected thereto by means of riveted joints reveals a condition which, in my judgment, provided a considerable disturbing influence, and was the immediate cause of failure of one of the columns * * * * Under actual load, the ends of the side cantilevers deflected vertically about 2 1/2 in. and moved horizontally toward the east about 3/4 in.The center cantilever deflected vertically about 3 5/8 in. and moved horizontally toward the east 1/8 in. (See note) This displacement of the ends of the cantilevers produced considerable movement in the fascia girder to which the cantilevers were rigidly riveted. The fascia girder in turn transmitted this movement to Cols. 1 and 2 to which it was attached by connections having the form and value of lever arms. * * * *

In my opinion the conditions at Cols. 1 and 2: The construction of the columns themselves, their high ratio of slenderness, the excessive unit-stresses, and the disturbing influence of the balcony cantilever, were responsible for the collapse of the theater, the collapse beginning with the failure of Col. 2. * * * *

The fascia girder forming the balcony rail in collapsing was bent back over the overhanging portions of the cantilever trusses. Had the balcony hit the auditorium floor before being struck by the roof it is apparent that this fascia girder would have been bent in the opposite direction. It should be noted in addition that in all of the cantilever girders the beam portion at the outer end shows a tension break in the top chord at its junction with the truss portion of the cantilever, indicating an excessive top-chord tension at some time during collapse. This could easily have been caused by a severe blow at the outer end of the cantilevers when the roof struck the balcony and could scarcely have been caused had the balcony struck the auditorium floor first. * * * *

Chief Inspector Ludwig's report says in part concerning this column:

It will be noted that only one flange of the column was braced, and that very inadequately. If the lower bracing had been in, the column would have been materially strengthened.To all intents and purposes the column had an unsupported length of over 60 ft., and its sectional area should have been determined by that length, instead of considering the bracing provided as effective and using the reduced lengths, as was apparently done.

The least radius of gyration of the column is about 2.54 in., and if the length be taken in round numbers at 60 ft. the value of 1/r is found to be equal to 283 instead of 120 as permitted under the Building Code. The actual load on the columns at the time of the collapse as nearly as can be estimated amounted to about 83 tons or 166,000 lb. The sectional area of the column is 21.22 sq.in., hence the load is 7823 lb. per sq.in.

These two columns were apparently the weakest link in the chain, and in consequence many have concluded that to the crippling or buckling of these columns, the initial failure was due. While theoretically it would appear that the columns should have failed under the load, yet nevertheless there is serious doubt as to whether or not this happened. An inspection of the columns after the collapse failed to show conclusively any such crippling or buckling as would naturally be expected. The columns are bent only at points of attachment of the bracing, such as it was; between these points comparatively little distortion was noted. The bends in the two columns are very similar.

Of the several theories advanced, not one is conclusive or satisfies all conditions.

In spite of this agnostic conclusion, Mr. Ludwig says farther on, in drawing conclusions as to better construction:

In spite of this agnostic conclusion, Mr. Ludwig says farther on, in drawing conclusions as to better construction:If the box type of column had been used in this instance instead of the H type, it is extremely probable that no collapse would have occured.With regard to the amount of bracing supplied both here and at the balcony truss columns, he considers that sufficient care had not been given to providing adequate bracing. He does not go into detail on this point, however. Earlier in the report, as quoted above, he says that in his opinion the roof columns should have been calculated as if unsupported laterally between their ends.

To supplement the various opinions on the failure of these roof columns above stated, one consideration must be mentioned that bears on the question whether the roof or the balcony fell first. Attention has already been directed to the fact that the roof columns did not buckle between bracing, but at the braced points. This is in itself peculiar, and hard to explain as a primary action. But in any event it means that if buckling of these columns was the first of the sequence, it must have occurred

through the lateral yielding at one of the braced points, with the instantaneous development of the buckling at this point into complete failure. Therefore, the corresponding braced point must be found in the wreckage somewhere far out of line of its original location, and torn away from its bracing.

through the lateral yielding at one of the braced points, with the instantaneous development of the buckling at this point into complete failure. Therefore, the corresponding braced point must be found in the wreckage somewhere far out of line of its original location, and torn away from its bracing.Refer to the plan, Fig. 3, showing the lay of the principal parts of the wreckage and Fig. 1, showing the points of attachment of bracing to the roof columns. At the upper braced point the column was held by the proscenium strut in one direction and was free in the other direction. The most probable buckling is transverse to the proscenium brace and therefore the point where the proscenium brace is attached to the column should be found far over to the north or south. This is not the case, the point in question lying fairly well under its original location. If the column, however, failed in the east-west direction (i.e., in the line of the proscenium brace), this brace would be pulled far away from the proscenium wall or pushed back into it. Neither event happened, as the sketch fairly well indicates, in either

of the two columns. At the lower braced point, where the fascia girder was attached, failure in north-south direction (transverse to the plane of the fascia-girder attachment) would have thrown this point of the column very far north or south. The aspect of the wreckage does not suggest such action. The entire situation, in fact, is out of harmony with the theory of primary roof-column failure, while agreeing with the view that the balcony failed initially and through the attachment of its fascia girder to the roof columns pulled these out of line and brought down the roof.

of the two columns. At the lower braced point, where the fascia girder was attached, failure in north-south direction (transverse to the plane of the fascia-girder attachment) would have thrown this point of the column very far north or south. The aspect of the wreckage does not suggest such action. The entire situation, in fact, is out of harmony with the theory of primary roof-column failure, while agreeing with the view that the balcony failed initially and through the attachment of its fascia girder to the roof columns pulled these out of line and brought down the roof.T. J. Foster (National Bridge Works) finds the explanation of the collapse in buckling of the balcony-truss columns (Cols. 3 and 4). As already mentioned, these columns were loaded to 15,000-16,000 lb. per sq.in. Fig. 12 shows the arrangement of one of these columns with respect to the balcony truss. The H-section of the column and the weakness of the outstanding legs of the angles against local crippling under bending stresses is

emphasized by Mr. Foster as well as the fact that the column was not braced except by its attachment to the truss, the truss being braced through its connection to the general balcony floor framing. Deflection of the truss in its vertical plane and movement of the truss backward through the general deflection of the balcony and the pivoting around the rear of the cantilever trusses is held to have subjected these columns to a bending and tipping action initiating failure of the outstanding legs of the column angles just under the bottom chord of the balcony truss. Mr. Foster's statement follows:

emphasized by Mr. Foster as well as the fact that the column was not braced except by its attachment to the truss, the truss being braced through its connection to the general balcony floor framing. Deflection of the truss in its vertical plane and movement of the truss backward through the general deflection of the balcony and the pivoting around the rear of the cantilever trusses is held to have subjected these columns to a bending and tipping action initiating failure of the outstanding legs of the column angles just under the bottom chord of the balcony truss. Mr. Foster's statement follows:The only explanation of the position of the balcony columns with respect to the balcony truss, the top chord of the balcony truss not being buckled, the excessive amount of loose concrete along the south side of the truss, and the break in the bottom chord of thetruss showing a break by shock, is that the south column failed first.

In looking for the cause of the failure of the south column, we find that the column was not overloaded in direct compression although the load actually on it at the time of the failure was greater than the estimated load that was to come on the column. We find that the deflection of the balcony truss at its center under its figured load would be about 5/8 in., and under the load actually on it at the time of the failure this deflection was no doubt over an inch. On account of the great slope of the balcony and the rigid connection of the cantilevers at the rear, a vertical deflection would cause almost the same horizontal deflection. The steel was also so thoroughly encased in concrete that this truss probably did not bow as much as if it was not incased, causing the truss to be pulled back for its entire length and causing an eccentric loading on the columns.

There was no bracing of any description to prevent the movement of the steel to the rear. The excess loading on the balcony must have caused deflection. This deflection must have been transmitted to the columns. It could not be transmitted to the columns without the balcony truss moving toward the rear of the building because the cantilevers were rigidly connected to the columns in the rear, and the great slope of the balcony with no bracing allowed the deflection caused by the great weight to push everything back.

That the collapse came when it did may be due in part to the influence of blasting. On the day of the collapse half a dozen or more blasts were set off in the rear part of thetheater, several of them late in the afternoon. The development of strains and deflections in the balcony structure would undoubtedly be hastened by the shocks of blasting. A resulting sudden shift would suffice to bring the balcony columns instantaneously to the crippling point, in view of their condition.

(South column at left; this has been blamed for the collapse.)

This theory is illustrated by the right-hand sketch in Fig. 12, indicating probable conditions of deflection. The top chord of the truss was so closely associated to the balcony slab that, if the slab just over the column moved back, the top chord must have moved back with it. The bottom chord, however, could twist between column and

nearest cantilever truss to suit the deflection curve of the column; thus the end portion of the truss became warped, and the column was subjected to a bending moment.

nearest cantilever truss to suit the deflection curve of the column; thus the end portion of the truss became warped, and the column was subjected to a bending moment.Henry W. Hodge, of the consulting firm of Boller, Hodge & Baird, examined the wreck with Mr. Foster, but did not go into calculations on the design. He also reached the conclusion that the balcony columns buckled first.

R. W. Boyd considers this theory and concludes against it:

My computation of the actual load on the column at the time of failure indicates that the load was approximately 198 tons, the actual intensity of stress in the column being approximately 15,900 lb. per sq.in. While this stress is greatly in excess of what should be allowed in safe design I am of the opinion that in the absence of a disturbing influence the column could not have failed under this stress. The movements were so minute that they could not have raised the stress in the column to an extent sufficient to have caused failure. * * * * In my judgment primary failure did not occur in either Col. 3 or 4.Chief Inspector Ludwig disposes of this theory with the following comment:

The deflection at the center of the balcony truss was slightly less that 1 3/4 in., and that of the side cantilevers about 1/2 in, and this latter, while undoubtedly having a tendency to produce a bending in the column, hardly seems sufficient to have caused the initial failure, especially if we take into consideration the weakness of the attachment of the bottom chord of the truss to the column. It is, of course, possible that the direct load on the column (366,000 lb.) in conjunction with the horizontal component due to bending may have been sufficient, but it seems remote.In considering the balcony column with regard to length, slenderness and buckling, it is probable that the square seating of the truss shoe on the column, with rivets connecting them, made the entire combination a column

from grillage up to top chord. This column, about 27 ft. long, held at the bottom by its anchor bolts and at the top by its close association to the balcony slab must have failed (if at all) by direct buckling under quiescent load, that was central except for the slight east-west bending produced by the twist of the truss. (See note) Buckling of a short solid-web column at 16,000-lb. loading with only minor bending, is not on record, so far as we know.

from grillage up to top chord. This column, about 27 ft. long, held at the bottom by its anchor bolts and at the top by its close association to the balcony slab must have failed (if at all) by direct buckling under quiescent load, that was central except for the slight east-west bending produced by the twist of the truss. (See note) Buckling of a short solid-web column at 16,000-lb. loading with only minor bending, is not on record, so far as we know.The report of Thos. J. Bird to the Fleischmann Bros. Co. states that the balcony truss failed in its tension-chord splice, and that this caused the collapse. He gives the following reasons for his conclusion:

1. The net area of the splice material in the bottom chord of the transverse balcony truss is considerably greater than the net area of the main section of the bottom chord, proving that the splice material must have been imperfect, or failure would have occurred in the main section before it would have occurred in the splice.The last mentioned fact supplements the deductions from the form of buckling assumed by the roof columns, as described earlier.

2. The cantilevers are pulled apart in the bottom chord back of the transverse truss, which indicates that this member was pulled apart by the fall of the transverse truss instead of by any force which might have been produced by the fall of the roof striking the balcony, which case would have buckled this member instead of pulling it apart, or would have pulled apart the top chord instead of the bottom chord.

3. As the end of the balcony fascia-girder and Cols. 1 and 2 (the roof columns) lay on top of the center part of the balcony fascia-girder, the center part must have fallen first and pulled columns 1 and 2 down afterward.

The theory of the tension-splice failure is discussed also by T. J. Foster and in the reports of R. W. Boyd and Chief Inspector Ludwig. Mr. Boyd gives the stress in the splice as "in excess of 22,000 lb. per sq.in.," and then says:

The theory of the tension-splice failure is discussed also by T. J. Foster and in the reports of R. W. Boyd and Chief Inspector Ludwig. Mr. Boyd gives the stress in the splice as "in excess of 22,000 lb. per sq.in.," and then says:Notwithstanding the fact that the truss is badly twisted and that there is a break in the tension splice in the bottom chord, there is every evidence that the failure of this truss was caused by the collapse and not by primary failure in one of its members. A close examination of the material at the broken splice and of the fracture of the top chord angles indicates that the material did not undergo much deformation prior to failure, as would have been the case had there been a critical stress long continued. There is every evidence that these breaks are the direct result of a load suddenly applied, causing very large instantaneous stresses. The falling of the roof onto the balcony would provide all of the elements necessary for the failure of the balcony truss as it actually took place.In part, the same argument is made by Mr. Foster, but he brings out some further facts against the tension-failure explanation:

It is practically true that an engineer as well as a layman takes some conspicuous point of failure and builds a defense about it instead of making a general analysis and then finding a cause. One of the conspicuous points is the splice in the lower chord of the balcony truss. The fracture of the steel plates at this point shows no reduction in area or elongation, and shows a crystallized fracture. Throughout the building where breaks occurred by tension there was a good reduction in area, elongation and fibrous metal, while in case of shock the breaks showed no reduction in area and the metal was crystallized. The metal in the broken parts of the bottom chord of the truss was examined and found to be medium steel. If the initial break had been at this point and the structure had given way due to the strain in the metal, there would surely have been a reduction in area, elongation and fibrous metal.The Bureau of Buildings regarded the question of this tension failure as of sufficient importance to have the material of the splice investigated. Prof. Wm. Campbell, Columbia University, examined samples of the splice material micrographically. The results of his examination

Another reason for this splice not being the cause of thefailure is found in the distribution of loose material resulting from the collapse. As can be seen from a front view, the entire collapse shifted to the south. Wreckage and loose concrete were deposited much more to the south of the center of the building than to the north of the center. We might disregard this as to the roof, but it is particularly true of the balcony truss, along the south half of which the loose concrete was piled much more densely than at any other portion of the building, showing that the loosening concrete was guided in this direction by the sloping steel; the steel could not slope toward this point unless this point went down first. The south wall showed that the truss fell to the south as far as it was able, and some beams which were a part of the gallery and which fell with it prevented the truss going further to the south, these beams making very heavy marks in the brick wall on their way down, cutting a gash in the wall 2 to 4 in. deep. If the initial break of the girder had been in the center the balcony would have doubled in on itself and the two broken ends of the bottom chord would have been found a considerable distance apart and the top chord would immediately have received the balcony load and would have buckled badly. The top chord did not buckle, and the two ends of the broken bottom chord were not over 2 ft. apart, and this is easily accounted for by the drawing back

of the north cantilever because this cantilever had not yet reached its resting place when the south end of the truss was down and the bottom chord broken.

If the lower chord had parsed first it would have tended to pull the tops of the two columns together and to push them farther apart on the line of the lower chord. The north column showed distinctly that the lower chord pulled the column and there is no distortion of this column at its top. The south column failed at the lower part of the truss and perpendicular to the line of the truss, and the flanges of the column at its top directly under the seat of the truss were buckled, also at right angles to the truss. If the truss had parted at the splice at the bottom chord it is inconceivable how the columns could have buckled in the manner described above.

show fairly satisfactory material in the splice, except in the lower flange plate. He reports on 8 samples of splice material as follows:

show fairly satisfactory material in the splice, except in the lower flange plate. He reports on 8 samples of splice material as follows:Sample 1: Some lamination and segregation, but not more than is commonly met with in this grade of steel.The two pieces described as brittle came from the lower splice-plate. The tension specimens in the testing machine showed 20,100-21,100 lb. yield-point and 29,100-27,800 lb. ultimate strength for the first, and 20,500 lb. yield-point and 23,900 ultimate for the second. The section at center of both was close to 0.50 sq.in., but as both broke in the grips the actual breaking stress is not easily stated. They broke without perceptible elongation or ductility, and showed fine crystalline fracture.

Sample 2. Good material.

Sample 3. Segregation and lamination, with the characteristic coarse grain of material finished hot. While not good, the material cannot be classified as bad.

Sample 4. Very low carbon. Parts of it show a good deal of manganese sulphide and slag in thin streaks; same remarks as on preceding.

Sample 5. Similar.

Samples 6 and 7. While of low carbon and of fine grainshowed too much segregation and must be classified as bad material, which is confirmed by marked brittleness in the testing machine.

Sample 8. Good material.

Chief Inspector Ludwig concludes against the view that the balcony truss failed first:

If this fracture of the member was the cause of the collapse of the structure, the member must have failed in tensionThe reference to hard or brittle material needs to be supplemented by a reference to the injurious effect of punching in such material. The splice-plates being punched in close spacing, extensive injury might result in the form of incipient cracking and hardening from the flow of material around the punch. Even steel which gives a good tension test may be thus injured.(a method of failure exceedingly rare) under a load a little in excess, if any, of 21,800 lb., only about one-half the elastic limit of the material. Again, a failure of the bottom chord in tension would ordinarily be followed by buckling or crippling in the top chord, and by some reduction of area or elongation in the bottom chord, and of this, as previously stated, the examination showed no evidence; on the other hand, the fracture has every appearance of having been produced by a sharp, quick blow, such as a heavy weight falling or the sudden displacement or removal of the supporting columns of the truss. The argument has also been advanced that the material forming the splicing of the bottom chord may have been of high-carbon steel; if this were so, the less reason for failure, inasmuch as its tension value would increase while its elasticity would drop.

Another fact not mentioned in the above discussions is the large amount of the secondary stresses which occur in the chords of shallow trusses. The existence of large secondaries is not merely inferred theoretically, but was proved in strain-gage tests on a New York skyscraper during erection several years ago. A large truss in this building, carrying several columns, was gaged on the top flange of the lower chord to measure the chord tension as erection of the stories above proceeded (the bottom flange was not accessible). The result was that no tension, but at some readings a slight compression was found; the bending of the chord, because of its own stiffness, decreased the chord tension to zero in the upper flange and, consequently, doubled the tension in the lower flange. Such action occurring in the balcony truss would increase the computed splice tension of more than 20,000 lb. per sq.in. by a considerable amount.

Following the clearing up of the wreckage of the Orpheum Theater, the structure was rebuilt on the original lines, but with increased sections in trusses and columns, with channels riveted over the column angles, and with added bracing of the columns. The original contractors built the new structure. It was completed in November, 1913, and is now in use.

Following the clearing up of the wreckage of the Orpheum Theater, the structure was rebuilt on the original lines, but with increased sections in trusses and columns, with channels riveted over the column angles, and with added bracing of the columns. The original contractors built the new structure. It was completed in November, 1913, and is now in use.